Access control is gaining increasing importance as companies realize they must know who is in their buildings at all times and keep unauthorized persons from entering. Faulty installation can defeat these goals.

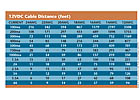

Insufficient cable gauge or too long a run may prevent enough electricity from being carried down the cable to a door to power its opening. Being too close to electrical or medical diagnostic equipment may interfere with the reading of access cards or result in phantom reads that unlock a door when no one is there.

Among the ways of preventing these problems are doing a site survey, following manufacturers’ specifications and using up-to-date equipment.

The importance of doing a site survey for a job cannot be overemphasized, stresses Eric Elsenbroek, systems specialist for distributor ADI, Melville, N.Y.

“When we’re asking questions, they don’t have specific answers,†Elsenbroek complains about some customers. “They never went to the job – somebody called them, and they call us, and we’ll ask them the questions, and they won’t know.â€

Sometimes such callers simply order the most expensive products so they will meet the maximum specifications, Elsenbroek maintains. “Just cover me on that – we hear that all the time,†he relates. “They don’t know where to put the power, we don’t know what the voltage drop is.

“You must visit the site unless the building does not exist, and then you must get a set of plans,†Elsenbroek insists. “You can’t just wing that.â€

Adds Mike Masten, training manager for ADI, “Know your environment. If I’m dealing with biometrics, some things are not rated for an outside or a humid environment. So I have to have the right product for the right application. Certain biometric readers don’t work very well where the door is being hit with sunlight. The sun may blind the reader.â€

1 Choose the Right Cable for the Job

“Wire and power are probably the two biggest things that cause dealers heartburn on the pure installation side,†Elsenbroek maintains.

ADI’s Masten agrees. “Our dealers want to cheap out on the power,†he concedes. “They try to get as tight as they can on the power requirements so then there’s not enough power to both feed the readers and take care of the locking hardware requirements.â€

Dealers should be sure to consider the specifications for a job as only 80 percent of what is needed, Masten thinks. “So our usual recommendation is that if you need 5 amps of power, then I’m going to give you at least 6.5 or 7 amps of power, because somewhere along the line you’re going to goof,†he believes.

One factor Masten points out is that smart card and biometric readers sometimes need more power. “Typically, control panels don’t have enough juice to power the new readers,†Masten declares. “Biometrics typically require more power or manufacturers recommend utilizing their own power supply. Some may use 13.8 volts instead of 12 volts.â€

The additional power may be needed to run the larger processors required to do biometric authentication and verification, explains Nathan Cummings, director of product line management, reader technologies for HID Corp., Irvine, Calif. “It’s basically just to do the mathematical functions to compare fingerprints – there is a heavy algorithm running behind it,†Cummings notes. “You want to do it as fast as possible and as accurately as possible.â€

Readers used to require only 125 kHz., but some of the newer smart card readers now draw 13.56 mHz. “Oftentimes you just can’t power it directly off the panel as you used to,†Cummings asserts. “It may not be as easy to install because you used to just hook it up to the panel, but now if the panel has met its maximum power draw, you would have the option to add an external power supply. It’s a different type of installation that may require additional costs.â€

This makes proper preparation even more important. “Read the specifications on the reader before you wire it into the panel and validate your power availability at the panel,†Cummings suggests. “Compare it against the reader you wish to install before you install it.

“There is such a variation between legacy panels,†he warns. “You used to be able to take any reader and it would work 90 percent of the time, and that’s just not the case now.â€

The importance of cabling also is emphasized by Bryan McLane, system design manager, The Systems Depot, Hildebran, N.C.

Most Weigand readers only operate with shielded cable in runs no longer than 500 feet, McLane notes. Some installers will try to use unshielded cable for a short run such as 30 feet or try running 520 feet of shielded cable for another installation. “They use what they have on their truck instead of what the manufacturer recommends,†he declares.

Installers do this because shielded cable is expensive, and it may not be stocked all the time by smaller dealers if they do not do many access control jobs annually, McLane explains.

If cable for Weigand installations needs to be longer than 500 feet, try extenders that can send the signals up to several thousand feet over twisted pair cable, he recommends.

For readers that have a higher current draw for a longer reading distance, such as 24 inches instead of 3 to 5 inches, try running an electrical source to them so the wire run will not have to be too far from an electrical source. Such longer-distance readers are used in applications where people in vehicles are gaining access with cards, McLane points out.

Installers should be sure to run more than enough wires to a door, Elsenbroek thinks. Sometimes they do not pull enough wires to the door for request-to-exit devices, he points out.

“They always end up short,†he complains. “One of the best things you can do is pull wires right the first time or pull extra conductors, so if you want to add something later, you have the conductors. We always recommend pulling wires from a drop ceiling so you have access from a junction box.â€

Besides running the right number of wires, running the correct wire also is a necessity, Elsenbroek notes. “You want to know what your environment is – is it a plenum or not, because that’s one of the biggest mistakes you can make,†he asserts. “You have to go back and pipe it, or pull new wire. If you’re not sure, put in plenum the first time. You may pay more, but it’s a lot cheaper than repulling the entire job.â€

2 Mount the Reader Correctly

Avoid mounting readers on metal unless there is no place else to put them, because doing so shortens their reading range, McLane maintains. Such reductions can be from 25 percent to 75 percent of the reader’s rated range, he estimates.

Jeff Smith, commercial operations manager for Vintage Security, Jessup, Md., notes that shortened reading ranges also are a function of the reader itself. “Selecting the right reader is another thing a lot of folks don’t do,†he observes.

A read range of 2 inches to 3 inches can be reduced to 3/4-inch with improper mounting, and customer expectations for read range must be clear before a job is specified to avoid complains after installation, Smith recommends.

Although sometimes only a metal door frame is available for mounting in applications like storefronts, the reduction in range will be noticed less if the reader has a longer range, such as 5 inches to 8 inches, instead of 1 inch to 3 inches, McLane advises.

Another option he suggests when a reader must be situated on metal is mounting it on something non-metallic, such as a block of wood or hard plastic.

For walls with metal studs 16 inches apart, try not to mount the reader on the stud, McLane suggests. Drywall thicknesses of 5/8-inch to 3/4-inch may be sufficient to retain most of the reading range, he thinks.

He also recommends following the Americans With Disabilities (ADA) guidelines for the installation height of access control panels and readers. “As far as the readers go, check the manufacturers’ specifications and consider them to be a stringent guideline,†McLane recommends.

Using readers specifically designed for mounting on metal doors is another approach to eliminate a reduction in reading range. After these installation considerations, the next biggest concern is the credential itself, maintains HID’s Cummings.

“A standard credential will give you the longest read range, but if you mix technologies inside the same card such as with a dual-technology card, then the read range will decrease a little bit because you have two different technologies inside the card,†he relates. Smaller access credentials such as keyfobs will have lower reading ranges too, Cummings notes.

3 Match Programming to Client’s Capabilities

Besides proper installation of the reader, installing and programming the access control panel is crucial. Programming access cards into a system can be a time-consuming task for the security dealer, systems integrator or end user.

“Programming is probably one of the most important factors of the whole job,†Vintage Security’s Smith declares. “Our biggest hurdle and challenge is now interfacing with the IT folks for the network options – you have to learn how to speak their language.

“I would say the biggest blunder we personally encountered was a job where everything was sold perfectly, but at the end of the day, the number of cards were not specified,†he recalls. The price of the cards had to be added to the project’s cost, which can be substantial depending on a job’s size. “So on the estimating and sales side, we have a quick form we fill out on every job,†Smith reports.

The form determines how many access cards are going to be used and then applies a formula to allow a certain amount of time on the job so the technician can program the cards.

Smith maintains his company receives fewer callbacks when its employees enter the cards into an access system themselves, and then train customers on how to make changes. “If you leave it up to the IT person to get this on the network, now you’ve just put another task on that customer,†Smith points out.

“I’m going to program the whole entire system for you, and then I’m going to train you on how to add, delete, change,†Smith explains about what he does for his clients.

“We’ve seen a lot of dealers install the software, get the basic parameters of the panel up and working, and then say, ‘You put in your own cards,’ which is good and bad. It forces the customer to learn how to do it, but at the same time, you’re not supporting your customer as you should,†he says.

The Systems Depot’s McLane thinks accurately gauging a customer’s skill and desire to manage an access control system is important. Be sure to choose a product for a customer that suits the customer’s level of expertise, he recommends. “The key thing is to understand what the customer can do and wants to do and determine your product from that,†McLane advises.

He also thinks planning for the growth of an installation is smart. “It’s doing the customer a favor and the installer a favor, and now you have an opportunity to go back and sell more product when the customer wants to upgrade,†McLane points out.

4 Run Interference

Electromagnetic (EMI) or radio frequency (RFI) interference can be overcome by using surge suppression filters or converting to twisted pair rather than shielded cable, which can act like an antenna, suggests ADI’s Elsenbroek.

How this happens is explained by L.J. Lynes, National Training School (NTS) instructor and National Burglar & Fire Alarm Association committee member. He also is the national training instructor for Stanley Security Solutions, Indianapolis.

“Only ground one end of the shielded wire,†Lynes advises. “If you ground both ends, you’ve made an antenna, and you’re asking for interference. On a normal basis, you wouldn’t run shielded wire on power-only devices such as locks because if anything happens, that shield can short it out.â€

Knowing what is in the area where access control panels and readers are to be installed is crucial when dealing with EMI and RFI, Elsenbroek advises. “You can get EMI in a hospital where the MRI room or CAT scan lab are putting out massive amounts of it,†he notes. “Every time somebody gets an X-ray, you don’t get in, or the door opens for no reason.â€

Another occasion for interference is placing in-and-out readers back-to-back on a door. “We hear that a lot,†Masten reports. “Place one up a little higher on the door than the other.â€

Lynes recommends using a dedicated raceway for security cable, never running it in conduit with electrical wire (Class 1 circuits), and maintaining minimum distances of at least 2 inches from high voltage circuits and anything else that gives off interference.

“One thing a lot of people overlook is inside the box,†he notes. “Inside the panel, your 110-volt circuit should be at least 1/4-inch away from the low-voltage wires inside the can.â€

Lynes also recommends keeping a clearance around the panel of at least 36 inches to allow easy access and a clear work area.

Kevin Welty, VertX support specialist for HID Corp., Irvine, Calif., points out that some systems only have 12VDC inside the panel. “The power supply is dropped down outside the panel in a separate box,†Welty explains.

The final tip is one that is heard a lot in the security business. “Read the manual – understand the requirements of the product before you put it in,†recommends The Systems Depot’s McLane. “I think that’s very important, and unfortunately, a lot of installers in our industry seem to think manuals are packing materials, and they’re not meant to be read.

Side bar: Use Up-to-date Computers

Don’t let your customers dust off their old computers with older operating systems like Windows 98 for use with a new access system, maintains Mike Masten, training manager for ADI, Melville, N.Y.

“Know the minimum specifications for what your access manufacturer is requiring,†Masten recommends. “The fact is, I could get little or no support on Windows 98 today.â€

Another factor even if support is forthcoming is that the old computer probably does not have the processing speed and memory required for today’s access control applications, Masten thinks.

Eric Elsenbroek, systems specialist for ADI, adds that the type of communication port on a computer also is important. Newer computers are using USB ports instead of the serial ones that access control equipment still uses. “Adding a USB to serial adapter is an additional cost you have to put in the job,†Elsenbroek points out, unless the computer obtained still has a serial port.

Side bar: No Automatic Opening for Vehicles

Jeff Smith, commercial operations manager for Vintage Security, Jessup, Md., recommends that vehicle access be provided by devices that require an action to be taken rather than simply moving within proximity of a garage door.

“Our thought process is, Wouldn’t it be better to let that end user make the selection whether they want the gate to open instead of plain opening it?†he asks. “You can choose to drive around and not go in if shady characters are around, but if you have a long-range reader, that gate is going to open.â€

Another advantage of a system that requires an action is that a record is created of who obtained access. A $20 device such as a garage door opener can leave the same security trail as an access card, Smith points out. An opener also means no reader need be placed outside on a pole.

“You put in a reader out there, and you can guarantee that thing will be smashed up, and you’re going to be replacing it,†Smith maintains. Other concerns are whether it meets the requirements of the Americans With Disabilities Act and whether people could run into it and sue. The opener can be installed above the door to prevent this.

Mounting an exterior access reader in an island with curbs is another way to prevent collisions, notes Nathan Cummings, director of product line management, reader technologies for HID Corp., Irvine, Calif.