Magnetic locks can provide “fail safe” operation so that, if power goes out, the lock will release, providing free egress.

By controlling entry to secured areas, magnetic locks and electronic door strikes serve a vital role in a security system. Ensuring that these devices are installed in a manner that is compliant with life safety codes, and other pertinent codes, is critical.

Codes that may be pertinent for installers include, among others, the International Building Code (IBC), the Universal Building Code (UBC), and the International Code of Convention (ICC). As Rich Hagala, customer support manager for Securitron Magnalock Corp., Sparks, Nev., explains, all of these codes are guidelines that local authorities can use when adopting their own code.

But local authorities can — and often do — add their own requirements on top of what is specified in the guideline codes. Before working in any new area, security dealers should consult with the local authorities, also known as the authorities having jurisdiction, or AHJs. Typically this is the same authority responsible for determining if a building is fit for occupancy.

“The local authority is usually county based,” Hagala says. He adds, however, that large cities often have their own unique requirements.

Locks or strikes?

Although both magnetic locks and electronic door strikes are aimed at securing a door except when a valid credential is presented, they handle the job differently — and as a result, their code requirements often are quite different.Door strikes typically are installed in the door jam and work in combination with the existing lock hardware. The lock hardware keeps the door secure until a valid credential is presented, when the strike temporarily releases the door. Because people inside the secured area can easily gain egress using the existing lock hardware, this solution typically does not present major code issues. One concern, however, is that door strikes require a hole to be cut in a door — a task that is often subcontracted to locksmiths. In selecting a door strike, installers should take care to select something that will not violate the door’s fire rating, which determines how long the door will withstand a blaze before it fails. If a suitable product cannot be found, a magnetic lock may be a better choice.

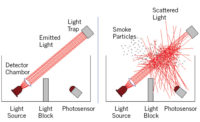

Magnetic locks consist of two pieces — a powerful electromagnet that is mounted to the door frame and an armature that is mounted to the door. Both are connected to the access control system, which temporarily cuts power to the magnet when a valid credential is presented. Unlike with door strikes, the conventional lock hardware is not used.

Many local authorities require that magnetic locks provide “fail safe” operation so that, if power goes out, the lock will release, providing free egress. The downside of that solution from the client’s point of view is that it also provides free access, potentially to the wrong people. But Hagala notes that some authorities favor magnetic locks because they enable emergency responders to easily gain entry.

In normal operation, an important requirement for magnetic locks is some type of request-to-exit device to enable people to leave the secured area. Often this may be a passive infrared detector or a request-to-exit button. These should operate independently from the access control system so that, if the access control system should fail, people can still gain exit.

Most local authorities also require magnetic locks to be connected to the fire system, which should release all secured doors in the event of an alarm and keep them released for a specific time period.

“Typically the fire alarm interface is made at the power supply that powers all the electronic locks,” explains Bryan Sanderford, national sales manager for Dortronics Systems, Sag Harbor, N.Y.

Sanderford adds that there also are situations where an installing company may need to plan for non-fire emergencies by providing a separate emergency release that’s not tied to the fire system.

The Americans with Disabilities Act also plays into the installation of door strikes and mag locks, Sanderford says. “It determines the height at which exit buttons must be mounted. And if there is mechanical hardware on a door used in conjunction with an electronic strike, the handles must be at an appropriate height.”

Medical facilities also may have some unique requirements, says Lauri Christiansen, director of marketing and business development for U.S. Lock, a lock distributor based in Brentwood, N.Y. In some cases, lock hardware may have to be made of anti-microbial or stainless steel, she said.

Emergency exits

If a building is a public space or one with an occupancy rating above a certain level, there may be some specific requirements regarding doors intended for emergency exit only.If the occupancy rate is above a certain level, it may be necessary to use a panic bar to enable quick egress and to sound an alarm. If there are multiple exit doors, all of them may have to release if any one of them is opened.

Depending on the specific type of location, local authorities may allow the panic bar on an emergency exit to operate as a delayed egress device, securing the door for a limited period of time when the panic bar is used.

Audit trails

Another regulatory requirement pertinent to securing access control doors is an increased emphasis on the protection of information. As Bob Swoope, vice president of sales for Alarm Lock Systems Inc., Amityville, N.Y. says, “Being able to lock up records is very important. Identity theft is such a huge problem.” Alarm Lock offers a stand-alone device that retrofits to the door. Authorized security personnel can use a separate portable device to download an audit trail from the unit.Salem, Virg.-based Medeco offers a retrofit electromechanical lock cylinder that has a built-in HID proximity card reader. As Tom Zuckerwar, marketing manager for Medeco’s E-Cylinders, explains, “When a credential is presented, the reader communicates with the cylinder and allows or denies access.”

Sidebar: Holding-force basics

One of the decisions that alarm dealers must make when selecting magnetic locks is the holding force, measured in pounds.“The rule of thumb is that a 180-lb. man can exert 850 lb. of impact on a door with his shoulder,” explains Bryan Sanderford, national sales manager for Dortronics Systems of Sag Harbor, N.Y. “For a perimeter door, an access control system should have a lock that will hold at least 1,000 lb. of force or more. The industry standard is 1,200 lb.,” he says. For interior doors, a lock with a holding force of 600 to 650 lb. may suffice. As Sanderford adds, “In interior office space frequently the doors and walls are such that they wouldn’t withstand 850 lb. of force.”

Dealers won’t save much money by buying a lock with 600 lb. of holding force rather than one rated at 1,200 lb. But the 600-lb. lock typically will be smaller, which could make it a more aesthetically appealing choice.