The ordinary perimeter door should be considered that point where the “physical security” of residential, commercial, and institutional structures begin. Windows are of course important, but FBI crime statistics in years past have routinely indicated that doors are the primary point of entry more than 80 percent of the time

In order to maintain security, it’s necessary to have a combination of mechanical and electronic devices on each door. In addition, electrified locking devices must be capable of automatically releasing the door for immediate egress in case fire is detected — which requires added integration between access control and a listed fire alarm system.

In this SDM feature, we’ll talk about some of the devices found on perimeter doors as well as fire doors within most commercial structures. Many if not most of these devices will be known to the average integrator/dealer while others may not be as well understood. The purpose of this article is to provide a fundamental basis for further investigation.

Partner Up When Necessary

The line between what a security integrator/alarm dealer and a typical locksmith does on a daily basis is usually wide and colorful (as opposed to fine and gray).

Generally, electronic techs do not get involved with mechanical locks, electric door strikes, and miscellaneous door hardware, but there’s no time like the present.

A relatively small percentage of security professionals actually do cross that line. Those that do usually do it in order to offer the best in mechanical and electronic protection from a single source — their own company. Not only that, but the extra money realized by doing so is well worth the effort. Yet, installing mechanical locks and door hardware can be challenging to an integrator/dealer. This is where it may be wise for you to partner up with one or more locksmiths in a nearby town — individuals that you can turn to for assistance.

“We believe that the security locks and door hardware trend is headed toward the electronic side, with a major push toward wireless solutions,” says Gary Martin of Camden Door Controls. “This varies between markets. As locking hardware has become more complex over the years, however, we’re seeing a trend toward integrators utilizing specialized lock installation companies.”

The key here is to assign one of your most promising technicians the task of helping the locksmith you partner with in order to learn by watching and assisting.

Generally, electronic techs do not get involved with mechanical locks, electric door strikes, and miscellaneous door hardware, but there’s no time like the present.

A relatively small percentage of security professionals actually do cross that line. Those that do usually do it in order to offer the best in mechanical and electronic protection from a single source — their own company. Not only that, but the extra money realized by doing so is well worth the effort. Yet, installing mechanical locks and door hardware can be challenging to an integrator/dealer. This is where it may be wise for you to partner up with one or more locksmiths in a nearby town — individuals that you can turn to for assistance.

“We believe that the security locks and door hardware trend is headed toward the electronic side, with a major push toward wireless solutions,” says Gary Martin of Camden Door Controls. “This varies between markets. As locking hardware has become more complex over the years, however, we’re seeing a trend toward integrators utilizing specialized lock installation companies.”

The key here is to assign one of your most promising technicians the task of helping the locksmith you partner with in order to learn by watching and assisting.

Mechanical Vs. Electronic

The job of securing most if not all facilities requires both mechanical devices in conjunction with electronic identification and control. One thing is for sure: mechanical door hardware will likely never disappear, although electronics appears to play a growing role in how and when these mechanical devices operate.

“There is no doubt that the trend for security locks and door hardware is moving toward electronics,” says Lester LaPierre, director of business development, electronic access control, ASSA ABLOY, New Haven, Conn. “This trend is reflected in both residential and commercial. As homeowners and tenants become more comfortable with electronic locks at home, the expectation to have the same level of security, convenience, and control is extended to the workplace.”

“One thing is for sure, mechanical door hardware will likely never disappear, although electronics appears to play a growing role in how and when these mechanical devices operate.”

In truth, there’s a ton of money to be made in the sale and installation of mechanical door hardware, such as push-button mechanical locks, push/panic bars, door hinges, door closers, kick-down door holders, door stops, kick plates, floor-mounted door stops, push plates, pull handles, continuous hinges, and the list goes on. But the trend in access control today is electronics, specifically in data acquisition, user identification, scheduling, manual door release, and other roles.

“More than 90 percent of our products are electrified or a mechanical component is routinely tied to an electronic solution,” says Kerby Lecka, marketing director, Security Door Controls of Camarillo, Calif. “One could say that the ‘trend’ is our reason for existence.”

Electrified devices include door cords, transfer hinges, automatic door openers, door holder closers, electric solenoids, electromagnetic door locks, electronic locks, door strikes, REX (request to exit) buttons, REX motions, door switches, and others (this list is certainly not conclusive).

“Automatic door operators also will be in even higher demand as the benefits of this application are used across market segments,” says Garrett Kaufman, president, Essex Electronics, Carpinteria, Calif. “Hand-E-Wave (Essex’s hands-free REX device) provides the hands-free door activation component, which can be used with an automatic door operator to provide a complete touch-free solution.” Essex is one of many manufacturers that have moved in this direction since the onset of the pandemic in 2020.

A single- or double-door egress electromagnetic lock (EML), designed to slow, not prevent someone from exiting. This model features voice prompts and a LED counter so occupants know how much time is left before the door(s) will open. || IMAGE COURTESY OF CAMDEN DOOR CONTROLS

For those who need additional help with automatic door openers, electromagnetic locks and other hardware, Camden Door Controls, Mississauga, Ontario, offers on-site training classes. “We tailor these training sessions to accommodate the specific needs of attendees,” says Gary Martin, product manager, Camden Door Controls. “In addition, earlier this year, we unveiled the ‘Camden Virtual Trade Show’ booth, which is unlike any other experience to hit the industry. It’s built using AVR (augmented video reality) — a software application that adds a layer of computer interface on top of a pre-recorded video presentation.”

Security Rides on Quality Door Hinges

If there’s any one spot on a door that receives the most wear and tear, it’s going to be the hinges. In fact, when you size up your access control jobs, it would be wise to visually scan the hinge side of each and every door that you’ll be performing work on — the objective being to verify the functionality of each and every hinge.

In medical facilities as well as other commercial environments it’s important to have a touchless egress solution, like this double-gang wave plate that's capable of activating an automatic low-energy door opener. || IMAGE COURTESY OF ESSEX ELECTRONICS

Even if the objective of a project involves a purely electrified solution — such as electromagnetic locks, card readers, and the customary egress devices — dysfunctional hinges can and will eventually cause operational problems for you down the road, if not sooner. Your company will end up running unnecessary service calls, presumably as part of your warranty.

For integrators and dealers who are not familiar with the various door hinges on the market, a good place to begin is with a list of the most common types currently in use. The following is a list of 13 from which you can Google all the details:

- Barrel hinge

- Butt hinge

- Butterfly hinge

- European hinge

- Flush hinge

- Knife hinge

- Mortise hinge

- Offset hinge

- Piano hinge

- Pivot hinge

- Soft-close hinge

- Spring hinge

- Strap hinge

Take photos of the hinges on each door and be prepared to render an option in your bid for hinge replacements when it appears that they might be necessary. The side benefit to this is if your client fails to upgrade and there’s a problem with one or more of these hinges … well, as they say, a picture is worth a thousand words.

The ANSI Hardware Grading System

The most significant point of importance to security professionals and their clients is that of the common perimeter door.

It’s your job to protect all points of ingress within residential, commercial and institutional structures — depending on the scope and the venues served by your company. When doing so, weigh the risks associated with each facility and plan to use the American National Standards Institute (ANSI) grade that makes the most sense.

Assumed risk is one of the reasons why door hardware is classified using a grading system: Grade 1, 2, and 3 — starting with the most secure. For those who may not understand these three basic grades and what they mean, here is a short description of each according to ANSI:

- Grade 1: Certification is commonly assigned to the strongest grade that ANSI recognizes for both commercial and residential uses. When a lock bears this certification, this is as good as it gets.

- Grade 2: Offers a higher degree of security for residential and light commercial. Products that bear Grade 2 are designed to provide excellent security and durability.

- Grade 3: Offers basic residential security. This is the lowest grade recognized by ANSI as it provides the minimal acceptable quality and durability for residential applications.

For more information on the door hardware grading system, check ANSI’s grade-relevant page here

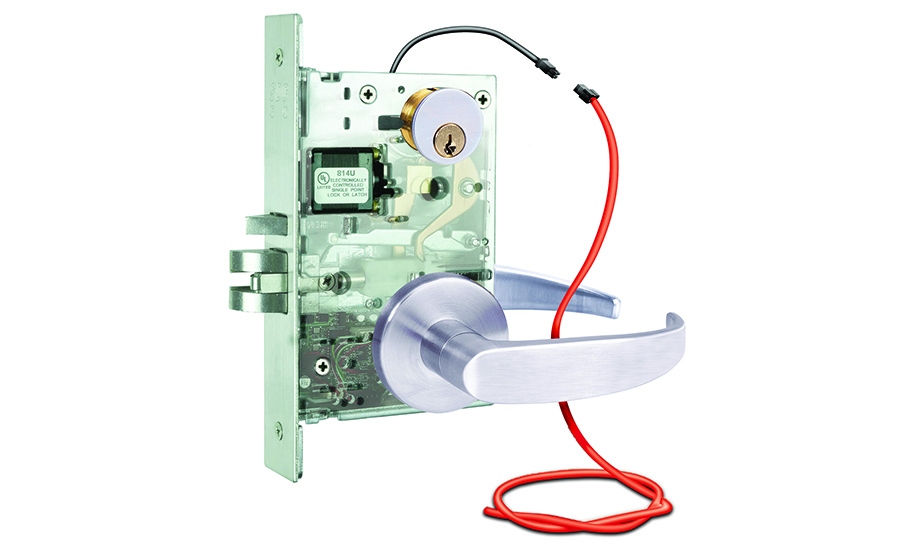

Electronic Locks: A Direct Replacement For Mechanicals

Sometimes there’s a real need to replace traditional mechanical locks with electronic models. This is made possible because electronic locks are specifically designed to fit into the same space within a door as their mechanical counterparts.

There are benefits to going electronic. First, electronic locks can provide a unique credential for multiple users, and owner/managers can manage them without incurring charges commonly associated with rekeying. Push-button mechanical and keyed locks do not provide this capability, unless you master the latter, which takes time and costs the client additional money. Whether it’s a high-tech RFID token, access card, mobile device app, or a manually entered PIN, electronic locks offer the most protection for the least investment, providing you match the ANSI security grade to the type of facility and individual security risks to be encountered.

This Grade 1 electrified mechanical lock simplifies egress by eliminating the customary REX hardware that’s required by fire code when installing an electromagnetic lock on a door, thus saving installation time and money. || IMAGE COURTESY OF SECURITY DOOR CONTROLS

Second, there’s the integration factor with other devices within the home, office, or commercial facility. Namely, many makes and models utilize radio frequency (RF) technology to send data to HVAC thermostats, alarm panels, lights, and other devices using Wi-Fi, Bluetooth (both traditional and low energy), Z-Wave, ZigBee, and NFC (near field communication). Through IoT (internet of things) devices and special mobile apps, they also can communicate with homeowners, business owners, managers, maintenance people, and other devices in general.

Third, through the use of electronic locks, many of the devices required by local and state fire codes can be omitted. Key here is the fact that most if not all of these relatively new access control devices are inherently designed to provide immediate egress through a single, instinctive action — usually by way of a lever or knob. This eliminates the need for an expensive electromagnetic lock, manual REX device, and REX motion.

How to Choose the Right Door Strike

The first thing that you need to consider when selecting a door strike is what the door and door frame are made of.

The most common types of materials to consider include wood, aluminum, and hollow metal.

Tip No. 1: Wooden door frames usually require an electric strike that contains a longer faceplate than is used on metal.

Tip No. 2: Hollow door frames are not always entirely hollow.

During the physical construction of a building, pieces of brick, mortar, and other items are often dropped into the steel frames that comprise a door assembly. One sure bet is to use a low-profile electric strike that houses the electric coil(s) up inside the door strike. By contrast, the coil(s) within most electric strikes are contained inside the frame itself, forcing you to chisel a space within the construction materials left behind. The expenditure of extra time and material can be avoided by using a low-profile electric strike.

Aluminum frames are usually not problematic, unless there’s a window involved. In this case, pay particular attention to where and at what depth you drill. Too much drilling in one direction or another can end up cracking the glass, which will cost you money.

It’s also important to note whether the door in question has an assigned fire rating. If it’s an inside door, such as a computer room, storage room, or something similar, the fire rating assigned to the electric strike must match the fire rating listed on the door.

The strength rating of the mechanical lock also must be considered when choosing the right electric strike. If the lock carries a Grade 1 commercial security rating, then the electric strike must carry the same Grade 1 rating.

The importance of fire-rated door assemblies cannot be stressed enough. It’s something that has existed for over a century now. Whether it’s a fire door, the mechanical locks used to protect them, or the door hardware that adorns them, your strike must match.

Be Aware of Fire Safety Code Issues

It’s not unusual for access control professionals to work on existing doors in old construction. The big thing here is knowing the fire codes that pertain to fire doors and egress openings, especially where it involves adding and changing hardware. Although we’re primarily interested in securing these portals, it’s our job to know what we can and cannot do without violating one or more of these statutes.

The bottom line is, a municipality requires that we observe these codes when we install locks, exit hardware, and other items that may impact the fire rating of the door itself. The other consideration is our encounter with existing doors in a client’s facility that no longer meet these codes. In this regard, there are four primary areas that we must be aware of:

- The visibility of a third-party listing label.

- Modifications already made to the door that may change its fire rating.

- The blockage of one or more unused or forgotten exit doors.

- Non-instinctive locking mechanisms that impede and prolong egress.

Numbers 3 and 4 are especially important because they’re designed to prevent unnecessary fire deaths at the “point of exit discharge.”

In brief, fire doors must bear a legible third-party label (such as UL) that can clearly be seen and read. If the door has been painted, or if you suspect that the door is not fire rated when it’s installed in a fire wall/barrier, you need to notify the facility manager before your work commences, and always take photographs. Code references include NFPA 80, Standard for Fire Doors and Other Opening Protectives, 2016, Sections 4.2.3, 4.3.1, and others. (link) Be sure the door is listed for fire, and don’t paint over the listing label during touch-ups.

If the door you’re about to work on requires physical changes, such as the removal of signage that could result in open holes, you must install steel fasteners that completely fill the holes, and fill the screw or bolt holes with the same material as the door or frame. To be safe and not sorry, obtain a current copy of the NFPA 80 standard from NFPA.

Last but not least, an adhesive-backed fire/smoke gasket is available for use on door frames to seal the top and sides. Its purpose is life safety because it’s capable of isolating one portion of a building from another so smoke cannot migrate from one compartment to another. The bottom line is, make sure you do your homework where it comes to fire codes and the ANSI hardware grading system.

The idea of making perimeter and select interior doors a major part of your access control program holds a great deal of promise from a profit standpoint. Over the last year and a half, hands-free access, which was already in place in many healthcare facilities, has become a significant force within the access/door marketplace, which is where automatic door openers and high-tech egress come into play in a big way.