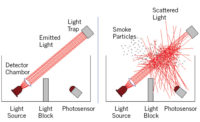

When it comes to systems smoke detectors, security dealers traditionally have had several different technologies available. One of the most commonly used types of detectors is the photoelectric detector, which uses an LED light source and a sensor to detect obscuration, which indicates smoke inside the detector. Another option is ionization detectors, which use an ionization chamber and a source of ionizing radiation to detect smoke. Heat detectors, which measure temperature, also may be a common initiating device that your company installs.

Many dealers have learned to follow two basic rules when it comes to smoke detection. As Tom Mecher, product marketing manager for Fairport, N.Y.-based Bosch Security Systems explains, ionization detectors tend to be most suitable for fast flaming fires, while photoelectric detectors are well suited for smoldering fires.

Those still may be good guidelines to follow. But recently, some new alternatives also have become available to dealers. Manufacturers have brought some new thinking to smoke detection with the goal of creating devices that work equally well for detecting numerous types of fires, in some cases by combining multiple types of detection in a single device.

Manufacturers also have continued to enhance the performance of technologies such as photoelectric smoke detection. Many of today’s smoke detectors contain microprocessors that use sophisticated algorithms to identify fire conditions. And as Mike Garavuso, product manager for Melville, N.Y.-based Honeywell Security explains, manufacturers such as Honeywell have continued to refine those algorithms.

In addition, manufacturers have made enhancements to their smoke detectors with the goal of making them easier to test and service.

ADVANCES IN PHOTOELECTRIC DETECTORS

Where possible, security dealers would prefer to install photoelectric smoke detectors rather than ionization detectors, comments Jay Levy, western regional sales manager for Hochiki America, Buena Park, Calif. A key reason is that ionization detectors contain small amounts of radioactive material, requiring them to be returned to the manufacturer at the end of their life for proper disposal, Levy explains. Another disadvantage to ionization detectors is that they lose sensitivity at higher altitudes, Levy says.

Recognizing this, Hochiki recently made a design change aimed at enhancing the sensitivity of its photoelectric smoke detectors. Unlike with typical photoelectric detectors, which have an LED and a sensor protruding into the chamber at the heart of the smoke detector, the LED and sensor on Hochiki’s new ALK-V smoke detectors are virtually flat.

In a traditional design, Levy says, “the smoke has to get around those protruding pieces.” By using a different approach, Hochiki has made its new detectors more sensitive, enabling them to detect smoke more quickly, he explains.

Due to enhancements that companies have made over the years, such as this Hochiki design, Levy believes some photoelectric smoke detectors now can be used in areas that might have required ionization detectors in the past. “We’re just as responsive across the full spectrum with photoelectric,” he comments.

Smoke detector manufacturers need to make sure, however, that in making their detectors more sensitive they don’t make them more susceptible to false alarms. Hochiki attacked this problem with its new detector design, Levy explains. The company’s new photoelectric detectors have a new screen around the chamber designed to help prevent steam and other potential sources of false alarms from getting inside the chamber.

“When you look at it, you wonder how smoke could get in,” Levy says. “The holes are small but it’s still as responsive to smoke but more resistant to nuisance alarms from steam.”

Bosch Security also has brought some new thinking to photoelectric smoke detector design with the goal of enhancing false alarm immunity. The company soon plans to introduce a smoke detector in the United States that has been available for some time in Europe, which has a second blue LED in addition to the traditional infrared LED. “By having two different wavelengths of light, you can get a much better indication of the size of the smoke particles,” Mechler explains. “By measuring the size of the smoke particles, we get better response than we’ve ever had with better false alarm immunity.”

COMBINATION UNITS

Some manufacturers have found it beneficial to build smoke detectors with more than one type of detector inside.

Bosch, for example, now offers a device that combines a photoelectric smoke detector with a carbon monoxide (CO) detector with the goal of reducing false alarms and enhancing responsiveness. “CO is a product of fire,” Mechler explains. “When you burn, you get some level of CO.”

Normally photoelectric detectors look for an obscuration level of about 3 percent, Mechler says. But in the combination device, the photoelectric detector normally looks for an obscuration level of 8 percent, making it less prone to false alarms. If the device senses even a minute amount of CO, however, the sensitivity is automatically adjusted to 3 percent.

The device can quickly detect a fire condition but experiences fewer false alarms caused by dust, dirt, and insects, Mechler says.

Bradenton, Fla.-based UTC Fire and Security also has a detector that combines a smoke sensor with a CO sensor. But UTC’s product works a bit differently. The two sensors operate independently. The CO sensor is not there to help the smoke detector sense fire, but instead serves as a separate life safety device for detecting unhealthy levels of carbon monoxide that can be caused by malfunctioning furnaces and other combustion-based devices.

More and more states are requiring CO detectors, and having the smoke sensor and CO sensor in the same housing adds an extra level of convenience, notes UTC product marketing manager Mike Ventola. “One of the unique things we’re introducing is a modular aspect,” he describes. “The end user can disassemble the housing in the field and replace the CO sensor.” That capability is particularly beneficial because CO detectors typically have a limited life of only about five to six years, Ventola says.

UTC also offers a smoke/heat detector that includes a photoelectric detector and three heat sensors. The three heat sensors are arranged so they can detect temperature changes equally well, regardless of the direction from which the heat is emerging, Ventola explains.

Honeywell also offers a device that combines a photoelectric and heat detector for use with its wireless systems or with systems that support point identification. In addition to signaling a fire alarm, the device can be configured to signal an alert if the temperature falls below a certain threshold, Garavuso says. That can be a useful feature for customers with a second home, alerting them if the heat in their second home drops to a level that could cause pipes to freeze.

Hochiki also offers a device that combines a heat detector and the same photoelectric detector used in the ALK-V. The combination device targets a market with unique needs, specifically, hotels and dormitories. The photoelectric detector functions as a stand-alone smoke alarm that generates only a local alarm when it detects smoke. But when a specific temperature threshold is passed, the device triggers an alarm that is reported to the control panel. The goal, Levy explains, is to avoid generating nuisance alarms from occupants smoking in their hotel or dorm rooms.

Manufacturers have made improvements to their smoke detectors with the goal of making the detectors easier to service. Some of these advances are the result of improvements they have made to the control panels with which the smoke detectors communicate.

Amityville, N.Y.-based Napco, for example, soon plans to release a combination fire and intrusion alarm panel that communicates with smoke detectors in a two-way fashion. This gives technicians the ability to easily adjust the sensitivity of any smoke detector in the system through the panel, explains Tom Karl, Napco vice president of sales development. The system is also capable of printing out a report indicating the sensitivity of all detectors in the system, a capability that could be particularly helpful in minimizing the time required for mandatory system inspections.

“The installer can call the system from the office on the morning of the inspection and walk in with the printout in his hands,” notes Karl.

A recent product enhancement from Bosch also could be helpful in making smoke detectors easier to service. As Mechler explains, “We have a small valve like on a basketball or football that can be used to clean out a smoke detector. You put a tube in the hole and it blows the dirt out.” Without this design, available on the company’s F220 series detectors, Mechler says, “You’re spraying dust into the detector or you have to take it apart and then clean it out.”

Newest NFPA Requirements Address Smoke Detectors Among Ceiling Beams

As we all know, smoke rises. But if a ceiling has deep beams, those structures can interfere with smoke’s path across a room, creating pockets and, depending where a smoke detector is placed, potentially delaying the detector’s ability to recognize a fire condition.

“Smoke has to collect and roll to the next partition, and if there are a lot of partitions, it can take a lot of rolling over until it hits the smoke detector,” explains Bryan McLane, vice president of sales for the National Training Center.

Recognizing this, McLane says, the National Fire Protection Agency added some new requirements in the 2007 and 2010 versions of the NFPA 72 code, which specifies how fire systems should be installed. In buildings that have ceiling beams with a depth greater than 10 percent of the ceiling height, there can be no more than two beams between detectors, and detectors can be no more than 15 feet apart. On sloped ceilings, smoke detectors are not required below a level that is 40 percent of the overall ceiling height.

For buildings with beams less than 10 percent of the ceiling height, there can be no more than three beams between detectors and detectors must be installed no more than 30 feet apart.

Other than this, most NFPA 72 requirements pertinent to smoke detectors have not changed since the 2002 version of the code, McLane says. Dealers should consult the version of the NFPA 72 code in effect in a specific jurisdiction for details about fire system installation, including requirements for smoke detectors.

Active Smoke Detector Targets Challenging Environments

Some environments are particularly challenging when it comes to smoke detection, including rooms with extremely high ceilings and areas that are extremely dirty. Either of those environments is a great candidate for the AIR-Intelligence detector, notes Barry Stahl, sales manager for Ashland, Mass.-based AIR Intelligence, the manufacturer that recently released the product.

The AIR-Intelligence detector is a photoelectric detector, but it uses a laser rather than infrared as the light source. That approach makes the device a thousand times more sensitive than a traditional photoelectric detector, Stahl says.

Perhaps even more unusual is the way the detector is installed. Technicians connect up to 165 feet of piping, typically ¾-inch PVC. Installers drill holes in the piping and the detector “pulls air through the piping network,” Stahl explains.