Not all such devices are manufactured equally, however. In fact, there are a broad array of choices and considerations for installers and their customers: holding force, finishes, local codes, the existing door and how it is mounted, and whether the door is interior or exterior. There is an electromagnetic locking device for just about any application, but it's not always easy to choose the best one.

Before dealers even start to consider buying an electric locking device, they should know what the local codes permit and require. Some jurisdictions do not allow the use of electromagnetic locks. However, electric strikes are widely acceptable. In many cases, codes require latching hardware as well as electric locks.

A good place to start the shopping process is to look for devices that have been certified by the Builders Hardware Manufacturers Association, according to Mike Tierney, product standards coordinator of the BHMA certification program. In cooperation with the American National Standards Institute (ANSI), BHMA has established minimum performance standards for electromagnetic locks and electric strikes. "The standards ensure the basic integrity of the product through temperature tests and cycle tests, including one performed for function," Tierney explains.

The current standards date from 1999, but BHMA and ANSI are in the process of updating them. Tierney expects the new standards to be approved by late spring 2004.

Tierney says that if the devices are to be used on fire doors, they should be UL listed or tested by another third-party organization. The same is true for delayed-egress locks, says John Schum, vice president of sales at Dynalock Corp., Bristol, Conn. Schum recommends buying American-made equipment; he warns that some imported products that have begun to appear in the market are not reliable in the materials used or in the actual holding force.

"If you have any callbacks because the lock fails, you've wiped out any savings you may have gotten by buying cheaper locks," he points out. "And the holding force of American mag locks is better."

Mike Phillips, technical services manager for Adams Rite Manufacturing Co., Pomona, Calif., agrees. "Don't skimp by using lesser products. You have to consider the security implications and the long-term durability of the product."

How Strong?

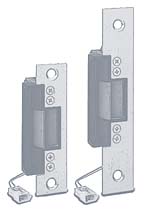

Holding force is the primary function of locks, and it varies widely among models. The prices of the lock – which range generally from $150 to $400 for mag locks and $100 to $300 for electric strikes – rise right along with their holding force. Choosing the most cost-efficient device and avoiding overkill depend on the application and even on the door on which the lock will be mounted, especially in a retrofit.Phillips advises surveying the opening before looking at the locking options available. "If there isn't already a locking mechanism that you can tie an electric strike to, you're better off with a mag lock," he explains. "But if you can bring wires in safely and work within the door you've got, use electric strikes."

Rick Geringer, vice president of marketing at Security Door Controls (SDC), Westlake Village, Calif., believes that any magnetic lock with a holding force of less than 1,000 lb. should be used only for traffic control. "Many people should be able to force a magnetic lock with 850 lb. holding force in seconds," he says. "At the same time, though, this is a benefit compared with light-duty electric strikes. The electric strike may break when forced, but a 500 to 650 lb. force magnet will release without damage, and the door will simply relock when closed."

The immediate environment is a factor in determining the finish on a lock, as well. Phillips suggests that buyers check that the finish is intended for exterior use if the lock will be used in an outdoor application. "Make sure the finish will hold up to a corrosive environment. Keep the installed products as protected as possible, or make sure the manufacturer has tested them in exterior use."

Aesthetics is another important consideration, especially for office buildings or other doorways that will be seen by customers. Geringer notes that magnetic shear locks mounted on all-glass doors provide significant holding force. When the lock is mounted on hollow metal frames, it is concealed by the frame's doorstop – a feature that provides better security as well as a cleaner appearance.

Emergency Exit

Electric strikes are available in two modes: fail-secure and fail-safe. The use of fail-secure strikes will ensure that the door will remain secure in a power failure, even if there is no back-up power source. A fail-safe strike, however, releases the door during a power loss to permit egress in an emergency."Magnetic locks are all fail-safe," Phillips notes, "so they need a power supply with battery back-up if security is an issue."

Keep in mind that the strongest lock in the world is useless if the door or door frame aren't able to stand up to the same pressure. Perimeter or exterior doors typically are stronger than interior doors, so it makes sense to use stronger locks on them. But with lighter-weight interior doors used primarily for traffic control instead of security, a locking strength of 500 to 900 lb. may be adequate.

Jerry Moore, operations manager for Cam-Dex Security Corp. in Kansas City and a member of the SecurityNet TechNet Group, always looks for some assurance of durability. With electric strikes, for example, the manufacturer may state that the product will withstand 500,000 uses.

Ease of installation is another important feature, since it saves an installer time. Moore also encourages dealers to find distributors and manufacturers that will provide plenty of product support. Some manufacturers offer 24-hr. tech-support hotlines, which come in handy if a system fails in the middle of the night.

He also advocates buying from a distributor who can help determine exactly what features are needed for the application in question. "Some manufacturers supply a CD with a utility that lets the dealer specify conditions to choose right lock," he says.

Schum suggests that dealers establish relationships with distributors who offer a full range of products and any other supplies they might need for installation. Such "one-stop shopping" helps ensure that they'll have what they need when and where they need it.

Getting Familiar with Magnetic Lock Features

John Schum, vice president of sales at Dynalock Corp., Bristol, Conn., has written three books about electric locking devices. He points out that as mag locks continue to evolve, buyers have more features from which to choose. Schum contributed the following definitions, which may help buyers determine which product is the best choice for any given application:Spike suppression. Usually a built-in electronic component, i.e., diode or MOV (metal oxide varistors) to prevent high-voltage spike from leaving the magnetic lock and entering the system.

Hook-up terminals. Some locks offer screw-type terminals, rather than lead wires, for ease of installation.

Voltage selection. Normally a built-in switch or jumper PIN that allows field selection of operating voltage (12V or 24V).

Rectifier bridge. A built-in or add-on electronic device that changes AC to DC. It allows the magnet to operate from a 12 or 24 VAC power source.

Adjustable time delay. An electronic component that allows the user to set a delay in re-lock after an authorized release. The typical adjustment time is 0-30 sec.

Door status switch. Generally, a magnetically operated reed switch concealed within the lock housing. Triggered by a small permanent magnet concealed in the armature, it signals the open/closed status of the door at a monitor panel or to create multi-door interlock systems. The switch output contacts are normally rated to carry only low-current loads, typically 1/4 to 1/2 A. It is also called a door position switch.

Lock status switch. A factory-calibrated electronic device built into the magnet assembly. It detects a critical loss of holding force due to low operating voltage or foreign material, damage or misalignment between the lock and armature mating surfaces. It provides open and closed dry contacts to monitor the secure/not-secure condition of the lock. The contacts are usually rated for low-current loads, typically 200-300 mA.

Anti-tamper switch. A miniature push-button or lever switch within the lock housing. It activates when an attempt is made to remove a housing mounting screw or the housing itself. Output contacts are normally offered in either open or closed, with current ratings anywhere from 1/2 to 6 A at low voltage.

Buying Checklist

- Check local building codes to find out what types of electromagnetic locking devices are permitted.

- Look for certification to the standards of the Builders Hardware Manufacturers Association and American National Standards Institute (ANSI).

- Check for UL listing.

- Match finish to the indoor or outdoor application.

- Ask about technical support during installation and afterwards.