A fiber optic link provides a path for light signals to travel between a transmitter and a receiver. For proper performance, this path must be free of defects and installation errors; otherwise, these may interfere with the light pulses as they pass through the cable.

There are many different devices and methods used to assure the quality of a fiber optic link. Just as automobiles have gauges and warning lights to indicate different engine conditions and mechanical problems, the testers used by a fiber optic technician provide different measurements and indicators of the usability of the fiber link being tested.

VISUAL TESTERS

To function properly, a fiber link must be “continuous,†meaning that it is not broken internally, either in the connector ends or within the fiber cable itself. Flashlights and visible lasers are used to perform this test. Visual testing yields a simple “no go†test. If the light or laser isn’t visible at the other end of the fiber link, then the fiber is unusable in its present state and requires further testing and repair.

Flashlights can be used to test multimode fiber links as long as three miles. This distance depends on the light power of the flashlight being used.

Fiber optic manufacturers supply flashlights with special adapters which allow direct connection of typical connector types, such as ST and SC, to the flashlight’s lens. The insertion of a colored film, such as red or green, makes the light more visible at the other end of the fiber link.

Manufacturers of fiber optic transmission equipment for the electronic security industry build their products to perform with a large percentage of potential signal loss between the transmitter and the receiver. Typically, a standard set of such transmission devices, also called “optoelectronics,†can function with as much as a 95 percent signal loss. Because of this wide performance margin, a fiber link that has been tested with a flashlight and seen to be continuous most likely will work fine for its intended use. In many cases, the flashlight is the only tester that a fiber optic technician may need. If the flashlight does not shine through the fiber link, a more sophisticated tester will be needed to find the location of the break.

Visible Laser Testers: Visible lasers produce a more powerful light and can provide more information to the technician than a flashlight. By coupling the fiber link to a visible laser, problems with connectors, breaks in the fiber near connectors or splices, and some bend radius violations can be located.

Testing with a visible laser will show the location of breaks within a fiber strand, provided that the outside jacket has been removed. A problem connector may be detected with the visible laser, provided that the connector has a plastic ferrule tip.

Manufacturers produce visible laser testers with various power levels and price points. A generic laser pointer, such as used in making presentations, can substitute for a much more costly fiber-specific testing device.

Both the visible laser testers and the invisible laser light sources used in some fiber transmitters can cause eye damage if repeatedly viewed. A technician always should view the reflected light from the laser, as opposed to viewing the light directly.

QUALITY TESTING OF FIBER LINKS

Although they can provide an indication of the usability of a fiber link, visible testers give a technician a limited amount of information. For a fiber link to be used over long distances or with maximum signal throughput, testers that produce a quantitative measurement of the fiber link’s quality are needed.

Two technicians must set up and connect the light source and power meter at opposite ends of the link, and use consistent procedures in order for test results to be accurate. Specifying bodies such as the EIA/TIA (Electronics Industry Association/ Telecommunications Industry Association) detail the exact procedures to be used when setting up and executing optical loss tests. The most commonly accepted testing methods are included in the EIA/TIA 568 standards for communication wiring.

Power meters can be very simple, with the dB light power value appearing on the meter’s display. More sophisticated testers can electronically record test values, download them to a computer, and provide other features. All optical loss testing results should be documented and saved.

Because of small differences in tolerances, a fiber link may have lower optical loss when measured from one end or the other. As many fiber links are installed but not immediately connected to transmission equipment, the standards require that fiber links be optical-loss tested in both directions that signal transmissions may travel.

An important usage of the power meter is for testing the output of a fiber optic transmitter. By connecting the power meter directly to the transmitter, it can be quickly determined whether the transmitter has the proper amount of light output.

The Optical Loss Test set is the generally accepted final test for a finished fiber optic link.

This device injects a pulsed laser light into one end of a fiber link, and displays the light energy reflected back to the tester from connector sets, splices, excessive bends, and the end of the fiber link itself. These testers operate at the standard wavelengths used in fiber optic transmissions.

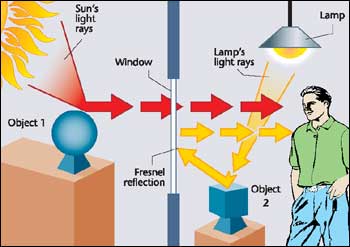

Connector sets and mechanical splices reflect light energy back to the OTDR because of Fresnel reflection. When a light wave passes from one medium to another, approximately 4 percent of the light energy is reflected back. This effect can be easily seen by looking out a window. You can see the outside, as well as reflections from within the room.

The lengths of fiber between connector sets will also reflect light back to the OTDR due to the effects of Rayleigh (ray-lay) scattering. Light energy traveling through the fiber core collides with water molecules, scattering some of the light energy back towards the OTDR.

OTDR traces require interpretation by a technician, as there can be circumstances that may hide or mask a potential fiber problem. For example, OTDRs generally cannot distinguish between two connector sets or splices that are within 50 ft. or less of each other.

The OTDR is a powerful testing tool. One of its advantages is the ability to ensure the quality of the entire fiber link without testing from both ends – a big plus when testing a fiber that is many miles long.

The OFL provides a read-out of distance to a loss event.

Some end users will require OTDR traces of completed fiber links as part of their contracted testing procedures. Whether required or not, OTDR traces should be stored for later comparison in the event of a fiber break or problem.

OFLs are less expensive and easier to use than OTDRs. However, OFLs do not provide the detail available with the OTDR’s trace.

Not all of these testing devices will be needed for every installation. A simple flashlight can be used to test the fiber link for continuity, and there is no reason not to simply connect the transmitter and receiver to the tested fiber link and complete the installation. With the addition of an Optical Loss Test Set, a technician can test fiber links for loss values, and transmitters for functionality.